What is DPF Active Matic?

Detergent for power washing of diesel particulate filters (DPFs).

Its formula has been developed considering the structure and particle matter accumulation type of DPF filters. Developed for use in closed-circuit cleaning machines. Laboratory tested.

Advantages of DPF Active Matic:

• Unblocks soot-clogged filter channels from the so-called soot cake.

• Removes trapped soot particles from within the porous walls dividing filter channels. Depth filtration.

• Release compressed ash from the rear ends of filter inlet channels.

• Cleans the internal part of the steel filter casing from soot, oil, and its deposits.

• Removes trapped soot particles from within the porous walls dividing filter channels. Depth filtration.

• Release compressed ash from the rear ends of filter inlet channels.

• Cleans the internal part of the steel filter casing from soot, oil, and its deposits.

It meets the following requirements:

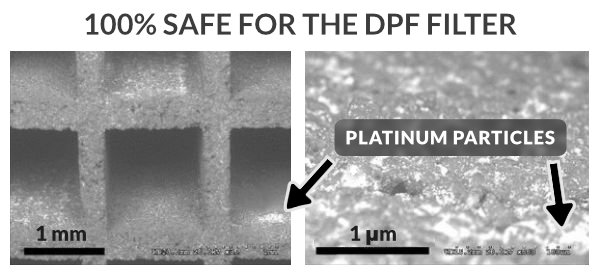

1. No negative impact on the catalytic coating of the filter – the catalytic coating is necessary to ensure proper passive regeneration.

2. Alkaline pH - increased cleaning efficiency.

3. Low foaming properties - safe for the water pump as excess foam could easily damage it. Excess foam blocks the friction of water particles.

4. The cleaned surface is not sticky once dried up – fresh soot is not easily absorbed into the filter surface.

5. Safe for sealing elements in the built in water instalation system.

6. It does not form a thick floating sediment layer inside the water tank, extending the service life of filter cartridges.

7. It contains corrosion inhibitors - safe for the steel filter casing.

8. Mild smell – its smell does not adversely affect the general working conditions.

2. Alkaline pH - increased cleaning efficiency.

3. Low foaming properties - safe for the water pump as excess foam could easily damage it. Excess foam blocks the friction of water particles.

4. The cleaned surface is not sticky once dried up – fresh soot is not easily absorbed into the filter surface.

5. Safe for sealing elements in the built in water instalation system.

6. It does not form a thick floating sediment layer inside the water tank, extending the service life of filter cartridges.

7. It contains corrosion inhibitors - safe for the steel filter casing.

8. Mild smell – its smell does not adversely affect the general working conditions.

How does DPF Active Matic work?

The product easily flows through the filter brick (monolith) through its unobstructed outlet channels, and then penetrates microscopic porous in the walls dividing monolith channels to wash dirty inlet channels.

Its formula softens highly compressed and attached particulates both in the inlet channels of the filter and in its microporous walls.

Carefully selected surfactants reduce the surface tension of the water based solution, leading to better effectiveness of the fluid in penetrating filter micropores. The wash-over effect removes all soot and ash loading from being cleaned DPF filter channels.

Thanks to the right fluid viscosity, the movement of fluid particles is similar to friction.

Its formula softens highly compressed and attached particulates both in the inlet channels of the filter and in its microporous walls.

Carefully selected surfactants reduce the surface tension of the water based solution, leading to better effectiveness of the fluid in penetrating filter micropores. The wash-over effect removes all soot and ash loading from being cleaned DPF filter channels.

Thanks to the right fluid viscosity, the movement of fluid particles is similar to friction.

Application of our detergent:

Prepare a bath in the machine tank – 5% solution (add 5,28 US gal water to 0.26 US gal of the fluid). Then add 0.052 US gal of the concentrate into each DPF before cleaning.

Recommended solution temperature: 140 – 176°F

Concentrate: 11-12 pH

Recommended solution temperature: 140 – 176°F

Concentrate: 11-12 pH